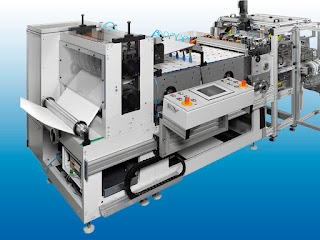

Advanced Stack Die machine to buy at Singapore Tridentent

Stacked die is an assembly approach in which or extra die are stacked and bonded in a single bundle. This become initially developed as a technique of placing memory chips in a single package deal to double the reminiscence density. The time period “stacked die” is often used whether the second one die is on pinnacle of the primary die or next to it. Nowadays, the generation has advanced in order that many die may be stacked, with the total limited by means of the package thickness. Stacked die device gives you mobility and manageability, all whilst keeping the very best level of performance possible. Our expert engineering staff delivers exceptional willpower to expand systems to satisfy the most demanding requirements.

The above bed stacking (abs) machine gets stamped laminations above the press bed via a changed bolster and presents them to the operator on the side of the click. Custom designed and built for every utility, automated load/unload systems increase pressroom production while at the equal time growing an efficient, operator secure paintings region. Computerized stacked dies machine load/dump systems is step one in a whole work cellular that begins with raw substances on the enter and finishes with a completed, equipped-to-deliver component on the output. The potential to custom design pre and publish press machines and then integrate with automatic load/sell off structures make it a exceptional fit for pressroom automation programs.

The underneath mattress stacking (bbs) device receives stamped laminations through the die and bolster, extracts them below the press and affords them to the operator at floor degree. The die ejection stacking (des) machine is designed to catch and take away elements being ejected from the upper die. The end crop stacking machine (ecs) is an cease reduce operation that allows the stacker to trap the lamination as it's miles being cropped from the give up . Semiconductor processing has split into various branches that have been optimized for different product types. One of the first splits came about with drams, whose need for capacitors required unique processing.

Some other split passed off as flash recollections required a method offering floating gates and specialized gate oxides. And advanced processors left the primary digital and analog markets at the back of with their wishes for excessive speed and excessive gate remember. Semiconductor processing has cut up into numerous branches which have been optimized for different product kinds. One of the first splits happened with drams, whose need for capacitors required unique processing. Some other break up occurred as flash memories required a manner offering floating gates and specialised gate oxides. And advanced processors in stacked dies machine left the fundamental digital and analog markets in the back of with their needs for excessive pace and high gate rely. read more...

Comments

Post a Comment